First, an overview of

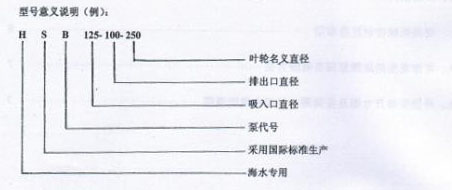

seawater pump is a single-stage single-suction cantilever pump, the pump structure, the reference to the German company FRIATEC technology, combined with the actual needs of domestic production applications, according to non-metallic pump special processing technology developed from the splint plate new product.

All the over-current components of the pump are made of non-metallic materials, ultra-high molecular weight UHMWPE or fluorine alloy with high mechanical strength, wear resistance and corrosion resistance. After reasonable formula, they are molded by high temperature and high pressure once and have high temperature resistance and no aging High strength, no toxin decomposition, etc .; Pump shell is made of high quality stainless steel or high quality A3 steel which is compression-resistant, impact-resistant and corrosion-resistant to the environment; all pump mechanical seals are made of wear-resistant and corrosion-resistant Pressureless sintering of silicon carbide refined. Mechanical seal design unique structure, reasonable structure, long service life.

Seawater dedicated pumps are widely used in seawater aquariums, seawater desalination projects, salt lakes and other projects with impurities and solid particles. They can also be used to transport any solid containing particles at a temperature of -20 ° C to 150 ° C according to different formulations Acid, alkali, salt, hydrochloric acid, nitric acid, strong oxidant, organic solvent, etc, are used in industries such as steel pickling, chemical industry, pharmacy, electric power, electroplating, food, synthetic fiber and papermaking. Can completely replace imported products.

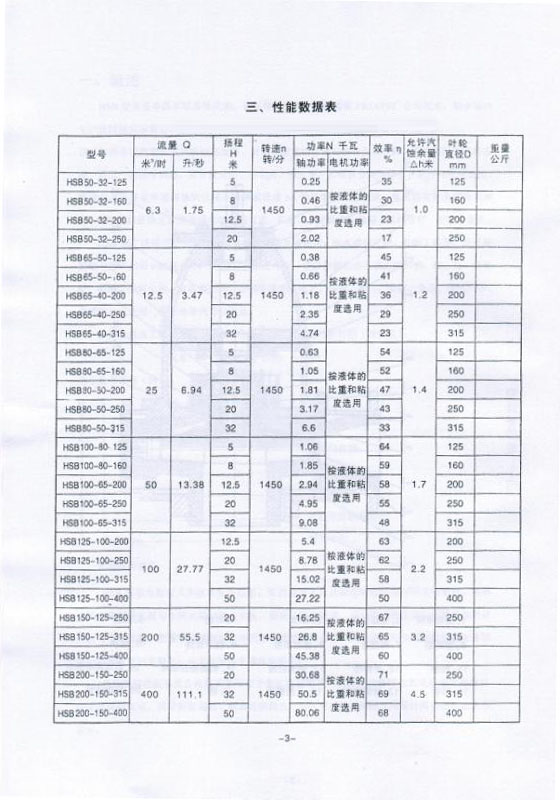

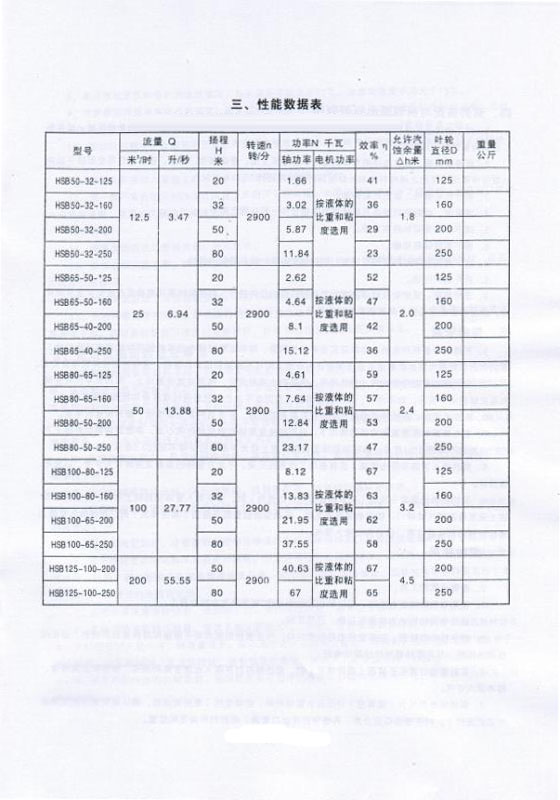

The maximum working pressure of the pump by 1.6MPa design, the performance range of this series of pumps (design points):

Flow: 5--16003 / h, lift: 5 - 80m

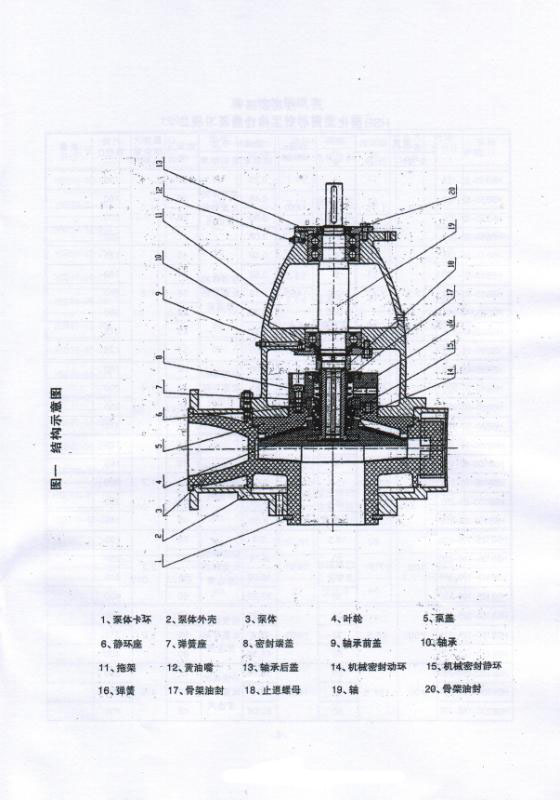

Second, the pump structure Description

Seawater dedicated pump single-stage single-suction centrifugal pump cantilever, pump rotation direction from the drive side to see clockwise rotation, the pump body with the front plywood and the middle bracket (steel splint) connection to To withstand the external pressure of the inlet and outlet pipes; supporting the front clamping plate and the middle bracket of the pump body; inserting the pump cover with the mechanical seal components through the positioning stop port into the suspension body part of the pump body and the middle bracket and fixed on the middle bracket , Supported by the suspension on the base.

Pump mechanical seal in the form of built-in single-wall balanced mechanical seal, the seal ring all made of silicon carbide material by pressureless sintering. The seal high temperature, excellent wear resistance. At the same time according to different conditions to design other structures of the mechanical seal.