1. Application: Diaphragm method caustic soda, phosphoric acid, vacuum salt, lactic acid, calcium lactate, alumina, titanium dioxide, calcium chloride, ammonium chloride, sodium chlorate, sugar, molten salt, paper, wastewater and other industries Evaporation, concentration, cooling, in order to improve equipment production capacity, increase the heat transfer coefficient of the heat exchanger for forced circulation.

2. Installation location: ground foundation (according to user needs to configure the elastic support) directly hung on the evaporator.

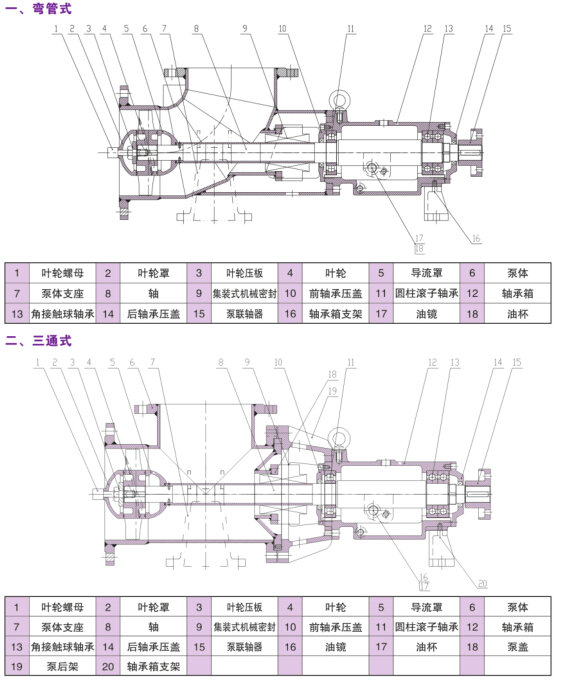

3. Pump Type: Horizontal

4. Transmission: direct drive, belt transmission, hydraulic coupling, universal joint transmission.

5 seal structure: modular mechanical seal, packing seal.

6. Pump manufacturing methods: casting, welding.

7. Performance range

Flow range: 300 ~ 23000m3 / h

Head range: 2 ~ 8m

Working pressure

: ≤ 0.6MPa Operating temperature: ≤ 170 ℃

Pump structure: casting or steel welding.

Overflow part of the material: ZG, 20 #, Ti, 1Cr18Ni9Ti, 304,316L, CD4MCu, 2205,2605

8. Model Description

Example: FJX-350

FJX: Evaporation Cycle Pump Code

350: Nominal diameter of the pump import and export (mm)

FJX-type axial flow evaporation pump, has the following characteristics:

1, low speed, the general speed of 980r / min or less, in line with the crystallization process requirements of stable operation.

2, excellent hydraulic performance, efficiency> 70% wide area, good anti-cavitation performance.

3, consider the pump medium flow direction into the horizontal direction, the vertical upward, the water flow on the pump shaft tremendous impact in the pump body has added a pump shaft jacket protection device, so that the subducting force of the medium transferred to the pump body, thus To ensure the stable operation of the pump, greatly reducing the media on the mechanical seal force, extending the life of the machine seal. The structure of the improvement of similar products in the country have taken a big step forward. In addition the pump body with a solid casting good rigidity, intermediate support structure and stability.

4, bearing box parts for the square long span of heavy structure, good stability, load capacity, reliable operation, compared with similar products in China to facilitate the installation of accurate (formerly domestic bearing box for the split). Front and rear ends were used radial short cylindrical bearings and heavy paired bearings. The bearings are used NSK (SKF) or domestic high-quality bearings.

5, advanced shaft seal, the use of impeller power seal and Burgmann fast double mechanical seal combination, external cooling flushing water, improve the working conditions of shaft seal, seal long life. Cylindrical bushing increases, compared with similar domestic products thicker wall thickness deformation.

|

model |

Flow Q |

Head H |

Speed |

Efficiency |

Shaft power |

With power |

|

FJX-250 |

300-683 |

3-6.36 |

980-1450 |

70-71 |

3.5-10.06 |

7.5-18.5 |

|

FJX-300 |

397-1783 |

2.4-7 |

980-1450 |

70-72 |

6.1-21.7 |

11-37 |

|

FJX-350 |

800-1260 |

3.3-4.5 |

980 |

72-75 |

12.7-16.2 |

22-37 |

|

FJX-450 |

1290-2858 |

4-4.8 |

730-980 |

74-78 |

18.7-44.5 |

37-75 |

|

FJX-500 |

1790-3910 |

4.3-6 |

730-980 |

73-78 |

30-76.7 |

55-132 |

|

FJX-550 |

2520-3700 |

4.1-4.5 |

730 |

75-76 |

41.2-56.2 |

75-110 |

|

FJX-600 |

3620-4900 |

4.1-4.7 |

730 |

73-77 |

53.9-82.5 |

110-160 |

|

FJX-700 |

3230-4220 |

4-4.6 |

480 |

70-78 |

45.1-72.5 |

75-132 |

|

FJX-800 |

4830-7230 |

4.2-5.3 |

480 |

73-77 |

95.5-120.2 |

160-185 |

|

FJX-900 |

5450-8100 |

3.8-4.5 |

380 |

75-76 |

83.1-111.7 |

160-185 |

|

FJX-1000 |

7180-10750 |

4.3-4.7 |

365 |

75-78 |

117.3-161.4 |

220-280 |

|

FJX-1100 |

8640-12900 |

4.3-4.8 |

330 |

75-77 |

150.5-196.2 |

280-355 |

|

FJX-1250 |

11500-17200 |

4.0-5 |

300 |

75-77 |

208.8-273.7 |

355-500 |

|

FJX-1500 |

16500-24700 |

4.0-5 |

250 |

75-77 |

299.6-384.4 |

500-630 |