UHB-ZK series of corrosion-resistant wear mortar pump is a single-stage single-suction cantilever centrifugal pump, the flow of components using steel-lined ultra-high molecular weight polyethylene (UHMWPE). The material is currently a new generation of international anti-corrosion wear-resistant engineering plastics pump, the most prominent advantage is that it has excellent wear resistance in all plastics, impact resistance (especially low temperature impact), creep resistance Degeneration (resistance to environmental stress cracking) and excellent corrosion resistance.

The pump is characterized by: multi-purpose, that is, a pump can adapt to a variety of conditions, such as the transmission of acid, alkaline solution or slurry; smelting industry, a variety of corrosive pulp; sulfuric acid various types of acid industry; Various types of industries such as sewage. The pump is both resistant to corrosion and wear, the use of a very wide range.

1, corrosion-resistant wear, a pump multi-purpose, acid-base serum slurry are applicable.

2, the pump body is made of steel-lined ultra-high molecular weight polyethylene with thickness of 8-20mm. The lining has good thermal deformation resistance, good resistance to cracking, falling off and high service temperature.

3, separate impeller, closed two, according to the media status optional.

4, sealed: K-type dynamic seal, mechanical seal.

5, medium: concentration of less than 80% sulfuric acid, nitric acid below 50%, various concentrations of hydrochloric acid, caustic soda, both for the slurry also apply to clear liquid.

Operating temperature -20 ℃ ~ 105 ℃, import diameter 32 ~ 350mm, flow 5 ~ 2600m3 / h, lift 80m or less.

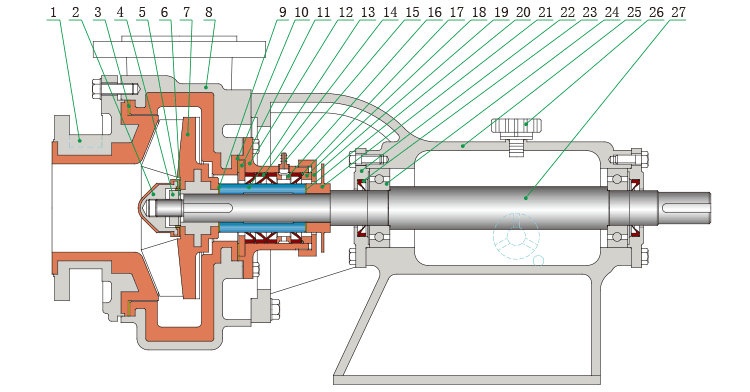

|

Serial number

|

Part name

|

Material

|

Serial number

|

Part name

|

Material

|

Serial number

|

Part name

|

Material

|

|

1*

|

Pump cover

|

UHMWPE + QT

|

10 *

|

Sealed box pad

|

F26B

|

19

|

Seal the lid

|

Fiberglass

|

|

2*

|

fasten the screw nut

|

UHMWPE + A3

|

11

|

Sealed box pad

|

PP

|

20 *

|

Sleeve pad

|

F26B

|

|

3 *

|

Pump cover pad

|

F26B

|

12 *

|

Sealed box

|

Fiberglass

|

twenty one

|

Block acid tablets

|

Fiberglass

|

|

4 *

|

Anti-rotation nut

|

A3

|

13 *

|

Sleeve

|

Silicon nitride ceramics

|

twenty two

|

Bearing side cover

|

HT-200

|

|

5

|

Hua Division

|

A3

|

14 *

|

K-ring

|

F4 / F26B

|

twenty three

|

Bearing oil seal

|

Neoprene

|

|

6 *

|

Lock nut L pad

|

F26B

|

15

|

Cooling faucet

|

PP

|

twenty four

|

Bearing

|

|

|

7 *

|

impeller

|

UHMWPE + A3

|

16

|

Water seal ring

|

Fiberglass

|

25

|

Bearing seat

|

HT-200

|

|

8*

|

Pump housing

|

UHMWPE + QT

|

17 *

|

O-ring

|

F26B

|

26

|

Oil plug

|

|

|

9*

|

Impeller pad

|

F26B

|

18

|

Top ring

|

PP

|

27

|

Spindle

|

40Cr steel

|

Note: serial number with "*" for the wearing parts for users to purchase spare parts reference.

1, Sulfuric acid phosphate industry: dilute acid, mother liquor, sewage, seawater, silica gel containing fluorine silicate, phosphoric acid slurry and other media delivery.

2, non-ferrous metal smelting industry: Particularly suitable for lead, zinc, gold, silver, copper, manganese, cobalt, rare earth and other smelting of acid, corrosive pulp, slurry (filter press with electrolyte) , Sewage and other media delivery.

3, chemical companies: all kinds of sulfuric acid, hydrochloric acid, alkaline, oil, liquid or slurry positions. Titanium Dioxide, iron powder production, all kinds of dyes, pigment production, non-metallic mineral processing and other industries.

4, chlor-alkali industry: hydrochloric acid, caustic soda, electrolyte and so on.

5, water treatment industry: pure water, high-purity water, sewage (leather sewage, electroplating sewage, electronic sewage, paper sewage, textile sewage, food sewage, domestic sewage, pharmaceutical wastewater, etc.).

6, steel companies: pickling system of sulfuric acid, hydrochloric acid post, with impurities in the sewage.

7, wet desulfurization circulating pump: can apply alkaline, acidic, corrosive jobs.

8, coal industry, coal chemical corrosive liquids, coal slurry delivery; washing coal with pump.

| Model / performance parameters |

Inlet / outlet diameter (mm) |

Flow rate (m3 / h) |

Head (m) |

Motor power (KW) |

Speed ??(r / min) |

| 32UHB-ZK-5-10 | 32X25 | 5 | 10 | 1.1 | 2900 |

| 32UHB-ZK-5-20 | 32X25 | 5 | 20 | 1.5 | 2900 |

| 32UHB-ZK-10-15 | 32X25 | 10 | 15 | 2.2 | 2900 |

| 32UHB-ZK-10-20 | 32X25 | 10 | 20 | 2.2 | 2900 |

| 40UHB-ZK-10-30 | 40X32 | 10 | 30 | 3 | 2900 |

| 40UHB-ZK-15-25 | 40X32 | 15 | 25 | 3 | 2900 |

| 40UHB-ZK-18-20 | 40X32 | 18 | 20 | 3 | 2900 |

| 50UHB-ZK-15-20 | 50X40 | 15 | 20 | 3 | 2900 |

| 50UHB-ZK-20-30 | 50X40 | 20 | 30 | 5.5 | 2900 |

| 50UHB-ZK-10-35 | 50X40 | 10 | 35 | 5.5 | 2900 |

| 65UHB-ZK-25-32 | 65X50 | 25 | 32 | 5.5 | 2900 |

| 65UHB-ZK-30-32 | 65X50 | 30 | 32 | 7.5 | 2900 |

| 65UHB-ZK-10-40 | 65X50 | 10 | 40 | 5.5 | 2900 |

| 65UHB-ZK-10-50 | 65X50 | 10 | 50 | 7.5 | 2900 |

| 65UHB-ZK-20-50 | 65X50 | 20 | 50 | 11 | 2900 |

| 65UHB-ZK-30-50 | 65X50 | 30 | 50 | 15 | 2900 |

| 65UHB-ZK-15-60 | 65X50 | 15 | 60 | 11 | 2900 |

| 80UHB-ZK-40-20 | 80X65 | 40 | 20 | 7.5 | 2900 |

| 80UHB-ZK-45-35 | 80X65 | 45 | 35 | 11 | 2900 |

| 80UHB-ZK-40-50 | 80X65 | 40 | 50 | 15 | 2900 |

| 80UHB-ZK-50-50 | 80X65 | 50 | 50 | 15-18.5 | 2900 |

| 100UHB-ZK-60-35 | 100X80 | 60 | 35 | 18.5 | 2900 |

| 100UHB-ZK-60-50 | 100X80 | 60 | 50 | 22-30 | 2900 |

| 100UHB-ZK-80-30 | 100X80 | 80 | 30 | 18.5-22 | 2900 |

| 100UHB-ZK-100-40 | 100X80 | 100 | 40 | 30-37 | 2900 |

| 125UHB-ZK-120-32 | 125X100 | 120 | 32 | 30 | 2900 |

| 125UHB-ZK-140-28 | 125X100 | 140 | 28 | 30-37 | 2900 |

| 150UHB-ZK-120-25 | 150X125 | 120 | 25 | 22-30 | 1450 |

| 150UHB-ZK-220-25 | 150X125 | 220 | 25 | 37-45 | 1450 |

| 150UHB-ZK-150-40 | 150X125 | 150 | 40 | 45 | 1450 |

| 150UHB-ZK-150-40 | 150X125 | 100 | 18 | 15-18.5 | 980 |

| 150UHB-ZK-200-35 | 150X125 | 200 | 35 | 55 | 1450 |

| 150UHB-ZK-200-35 | 150X125 | 135 | 16 | 18.5 | 980 |

| 150UHB-ZK-300-20 | 150X125 | 300 | 20 | 55 | 1450 |

| 150UHB-ZK-300-20 | 150X125 | 200 | 10 | 18.5 | 980 |

| 200UHB-ZK-300-32 | 200X150 | 300 | 32 | 75 | 1450 |

| 200UHB-ZK-300-32 | 200X150 | 200 | 15 | 22-30 | 980 |

| 200UHB-ZK-350-30 | 200X150 | 350 | 30 | 75-90 | 1450 |

| 200UHB-ZK-350-30 | 200X150 | 240 | 15 | 30 | 980 |

| 200UHB-ZK-400-28 | 200X150 | 400 | 28 | 90 | 1450 |

| 200UHB-ZK-400-28 | 200X150 | 270 | 13 | 30 | 980 |

| 150UHB-ZK-550-30 | 200X150 | 550 | 30 | 110-132 | 1450 |

| 150UHB-ZK-550-30 | 200X150 | 370 | 14 | 30-37 | 980 |

| 250UHB-ZK-600-32 | 250X200 | 600 | 32 | 110 | 1480 |

| 250UHB-ZK-600-50 | 250X200 | 600 | 50 | 160 | 1480 |

| 250UHB-ZK-800-32 | 250X200 | 800 | 32 | 132 | 1480 |

| 250UHB-ZK-800-50 | 250X200 | 800 | 50 | 200 | 1480 |

| 300UHB-ZK-1000-32 | 300X250 | 1000 | 32 | 160 | 1480 |

| 300UHB-ZK-1000-50 | 300X250 | 1000 | 50 | 250 | 1480 |

| 300UHB-ZK-1200-32 | 300X250 | 1200 | 32 | 200 | 1480 |

| 300UHB-ZK-1200-50 | 300X250 | 1200 | 50 | 315 | 1490 |

| 350UHB-ZK-1400-32 | 350X300 | 1400 | 32 | 250 | 990 |

| 350UHB-ZK-1400-50 | 350X300 | 1400 | 50 | 355 | 991 |

| 350UHB-ZK-1600-32 | 350X300 | 1600 | 32 | 250 | 993 |

| 350UHB-ZK-1600-50 | 350X300 | 1600 | 50 | 400 | 991 |

| 400UHB-ZK-2000-32 | 400X350 | 2000 | 32 | 315 | 993 |

| 400UHB-ZK-2000-50 | 400X350 | 2000 | 50 | 500 | 991 |

| 400UHB-ZK-2300-32 | 400X350 | 2300 | 32 | 355 | 993 |

| 400UHB-ZK-2300-50 | 400X350 | 2300 | 50 | 560 | 991 |